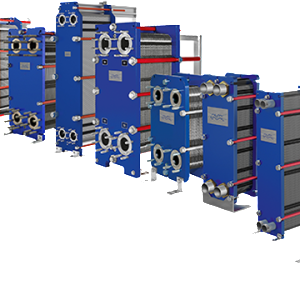

Product Description

Alfa Laval WideGap gasketed plate-and-frame heat exchangers are suitable for fibrous liquids, for highly viscous fluids and for fluids containing coarse particles. Typical applications for Alfa Laval WideGap heat exchangers are sugar, bioethanol and pulp and paper processes. Depending on the duty, WideGap heat exchangers can be configured either with wide-wide or wide-narrow channels. This makes the units suitable for heating, cooling and interchanging duties.

Tailor-made

Alfa Laval WideGap is tailor-made for handling fibrous fluids and fluids that are very viscous. The smooth port design ensures that fibres don’t get stuck at the entrance.

Equipped with well-designed features, Alfa Laval WideGap heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket –a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Glued gasket –a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition.

Additionally, the pressure plate roller, the bearing boxes on tightening bolts, and the 5 point alignment system with reinforced hangers make opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

Alfa Laval WideGap is quick and easy to modify if process parameters change. Our team’s expertise and the availability of parts bring you peace of mind.

Peace of mind

Alfa Laval global service network is never far away.

Features and benefits

- More heat recovery reduces energy cost

- Lightweight, requiring much less floor space

- Increased uptime

- Flexible solution – reconfiguration of plates to fit new duty

Reviews

There are no reviews yet.