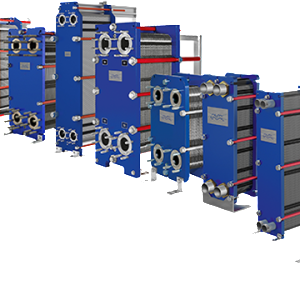

Product Description

Alfa Laval FrontLine is the premium range of heat exchangers used in diary, food, beverage and other hygienic applications requiring gentle product treatment, long operating time or superior cleanability. In comparison to the Alfa Laval BaseLine range, also used for hygienic applications, the FrontLine range meets the highest demands on hygienic control and it is the superior choice for heat sensitive media. FrontLine has a flexible design and it is possible to rebuild the connections.

Efficient design

Efficient design Alfa Laval FrontLine allows a flexible design with plates tailor-made for demanding hygienic applications. The plate pattern and the pressing depth are designed for gentle, uniform heat transfer for sensitive dairy, food and beverage products. The glue-free gaskets are made with FDA-compliant materials which are easy to maintain and have a long service life.

The frame is available for multi-section applications and is easy to disassemble for inspection, cleaning, and service. The connection plate corners are interchangeable and the heat transfer plates can easily be added or removed. This makes the FrontLine quick and easy to modify in the event that process conditions change.

Plate types for different hygienic needs

FrontLine is available with 3 different types of plates, all of which are designed for sensitive, hygienic applications and uncompromising cleanliness.

- Clip plate – The Clip plate has a chevron plate pattern designed for hygienic conditions. The entry points, the distribution area, and the shape and depth of the pressed plate pattern allow for optimal performance.

- Clip plate Gemini double wall –The Clip plate Gemini double wall consist of two plates pressed together.This prevents cross contamination between fluids in case of leakage through the plates.

- Clip plate WideStream –The Clip plate WideStream has a wider plate pattern with fewer contact points which makes it ideal for products containing pulp or fibres.

FrontLine’s plate pattern and pressing depth are designed for gentle, uniform heat treatment of sensitive dairy, food and beverage products. Examples of applications are:

- Pasteurization of yoghurt, ice cream, and beer

- Pasteurization of fruit juice with fibres

- Heating and cooling of viscous products

Alfa Laval BaseLine is recommended for less demanding hygienic applications.

Automatic model for easy use in pasteurization with high throughput

Alfa Laval’s FrontLine Automatic is an extended version that has a motor and a PLC based control system for automatic opening and closure of the heat exchanger. This is suitable for larger units in dairy pasteurization with high throughput where there is requirement for frequent inspection and cleaning.

Peace of mind

Alfa Laval global service network is never far away.

Reviews

There are no reviews yet.